Various industries are seeing an increased need for low-latency, high-bandwidth communications. Consistent with other remote communications markets, the growing offshore aquaculture sector is experiencing its most rapid adoption of technology ever, which is fueling the need for high-throughput communications. While the fish farming industry traditionally has not been an early adopter of new technologies, there is now a huge technology revolution focused on fish cultivation. This is due in part to an increase in fish production per annum over the last 40 years – from 71 million tons in 1978 to 178 million tons in 2018. Over this period, fish farming’s share of production has increased from 6% to 46%, representing an increase of around 20 times in real terms.1

At present, offshore fish farms are deploying emerging technologies to increase yields, reduce deteriorating environmental conditions, and lower operating costs.

Deployed technologies include high-definition (HD) cameras, sensors, and automated processes, right through to operations centers where operators have all the required data, images and information at hand for controlling fish farms remotely. Assisted by HD cameras on fish farming barges, remote operators can adjust and control feedings based on the fish’s age, size, hunger levels, eating behaviors and more. Operators can monitor activities and respond accordingly, for example by turning off a feeding, or moving a feeding to another area.

The feeding process is the largest operational cost for fish farms. Therefore, by preventing overfeeding farm operators can significantly reduce OPEX costs and negative environmental impact. When offshore pens are overfed, excess feed finds its way the seafloor, giving rise to undesired growth of plankton, sea plants and algae. As this is considered pollution, which is closely monitored for its environmental impact, minimizing feed loss is extremely important to fish farm operators.

These deployed technologies demand low-latency communications, as operators must respond and act in real time. Moreover, HD cameras are bandwidth-intensive devices, with each farm operating multiple cameras. While setups vary from farm to farm, a typical deployment may involve 6 to 8 cameras. With each camera requiring above 20 Mbps, capacity requirements per site range from 150 Mbps up to 300 Mbps. Adding to this, each offshore barge has multiple pens.

The Need for Stabilized Connectivity

Now that we have established the need for high-capacity, low-latency communications for offshore fish farms, let’s look at the locations of their barges. Often exposed to tides, winds and waves, offshore barges are not fixed in the sense that they do not have the same heading at all times. This means that the communication link must auto-adjust as the barges move up-and down or side-to-side due to winds, waves and tides.

Ceragon’s PointLink for Offshore Fish Farms

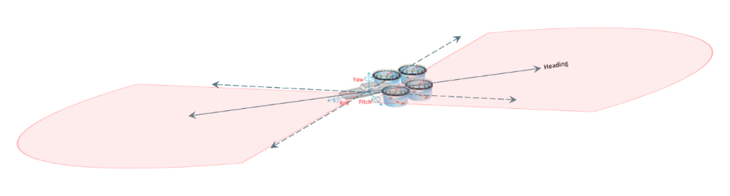

The PointLink stabilized communication solution delivers great value to the offshore aquaculture industry, as it maintains alignment regardless of the yaw, pitch or roll of the barge.

PointLink installations on fish farm barges

POINTLINK SOLUTION ADVANTAGES FOR FISH FARMS

LAYS THE FOUNDATION FOR: |

SUPPORTS THE IMPLEMENTATION OF: |

DELIVERS BUSINESS VALUE THROUGH: |

|

|

|

For more information about Ceragon’s PointLink platform

As aquaculture continues on its digitalization journey, Ceragon is proud to be a value-added partner to many offshore fish farms around the globe.

1. The State of World Fisheries and Aquaculture 2020 (site)

2. The State of World Fisheries and Aquaculture 2020 (written report)